Workmanship Guaranteed

Licensed & Insured

Upfront Fair Pricing

Finance Available

Apricus Solar Hot Water Repairs Brisbane & Gold Coast

Fast, reliable repairs for Apricus solar hot water systems.

Evacuated Tube Specialists | Heat Pipes, Manifolds, Sensors & Controllers | 15-Year Warranty Support

Apricus Solar Water Repair Specialist

Same-day service at no extra costs

We drive fully stocked vehicles

Upfront, clear pricing

Solar accredited plumbers & electricians

Quality guaranteed

📞 Same-day Apricus solar water repairs: 0482 080 423

Apricus Solar Hot Water Repairs Brisbane

Fast, reliable repairs for Apricus solar hot water systems.

Evacuated Tube Specialists | Heat Pipes, Manifolds, Sensors & Controllers | 15-Year Warranty Support

Apricus Solar Water Repair Specialist

Same-day service at no extra costs

We drive fully stocked vehicles

Upfront, clear pricing

Solar accredited plumbers & electricians

Quality guaranteed

📞 Same-day Apricus solar water repairs: 0482 080 423

Common Apricus Solar Hot Water Problems We Fix

Apricus evacuated tube systems are high-quality but have unique failure points. We're Brisbane's specialists in heat pipes, manifolds, and tube replacements with 15+ years experience.

Heat pipe failures

Tubes lost vacuum

Manifold temperature failure

Manifold cracking/splitting (freeze damage)

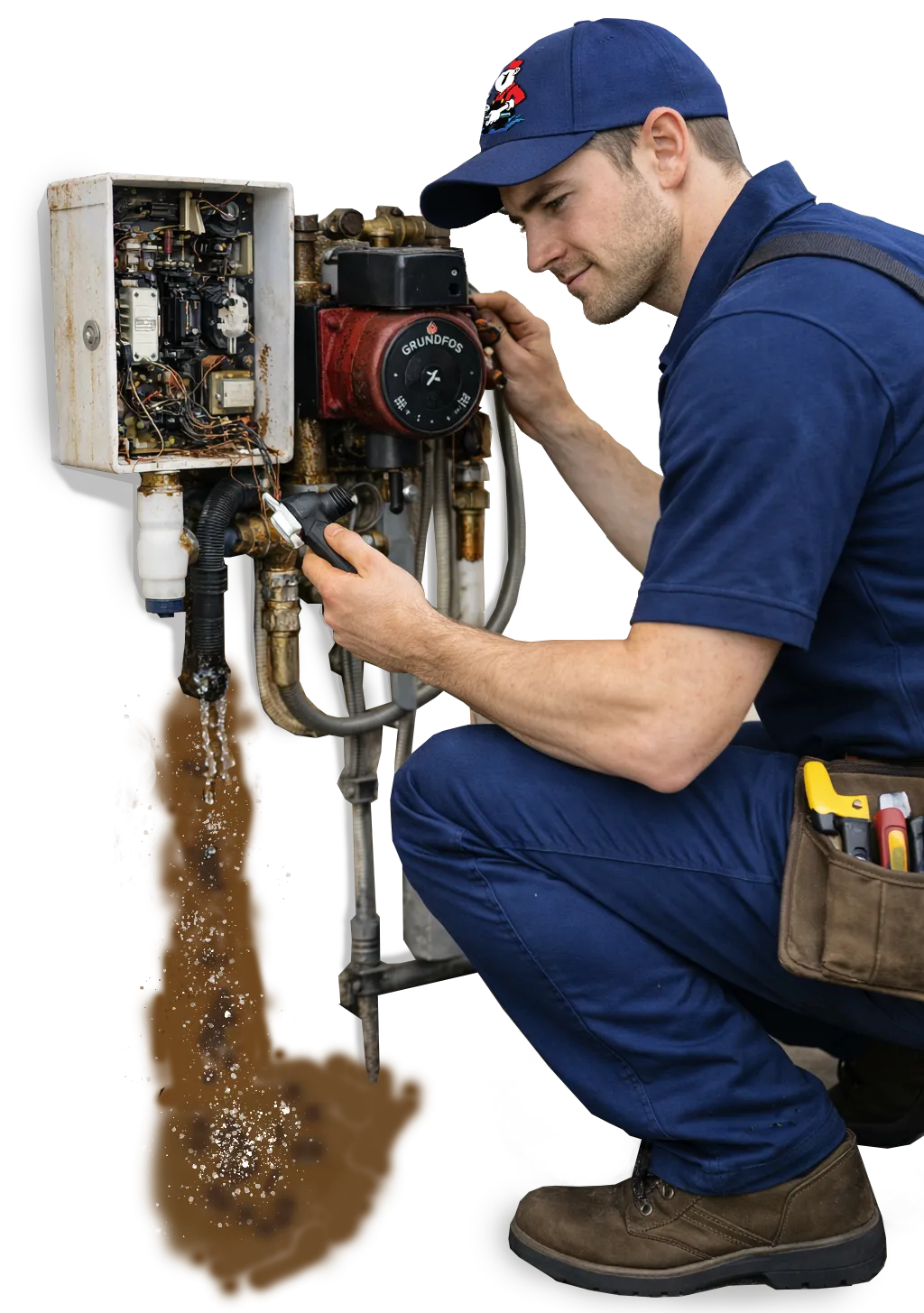

Grundfos circulation pump failure

Resol controller failures

Heat pipe migration/disengagement

Tank anode depletion

System running at night

Controller adjustment

Cable damage

Insufficient Hot Water/Poor Performance

Evacuated Tube Specialist

We understand heat pipe technology, vacuum testing, manifold repairs, and the unique challenges of Apricus systems. Not all plumbers do!

Proper Diagnostics

We use infrared thermometers, vacuum testing, and systematic troubleshooting. We don't just replace controllers hoping it fixes the problem!

Part & Warranty Support

We help you navigate Apricus's 15-year heat pipe warranty and source replacement parts. We know the warranty process and documentation required.

Same Day Service

Emergency repairs available across Brisbane. We understand you need hot water now, not next week when parts arrive from interstate.

Honest Assessment

We'll tell you if it's heat pipes, sensors, pump, or controller. We don't sell unnecessary parts. If system is beyond economical repair, we'll advise replacement.

Quality Repairs

All work warrantied. We use proper heat sink grease, secure sensors correctly, purge systems properly - the details that prevent repeat failures.

Apricus Models We Service & Repair

We repair all Apricus evacuated tube systems installed across the Gold Coast and Brisbane. From 20-tube to 44-tube collectors with all tank sizes.

Apricus Collectors

Standard Systems

• AP-20 (20 tubes) - Small systems, 250L tank

• AP-22 (22 tubes) - VIC/TAS models for colder climates

• AP-30 (30 tubes) - Most common Brisbane size, 315L tank

• AP-44 (44 tubes) - Large systems, 400L tank

System sizing guide:

• 1-3 bedrooms: 20-22 tubes with 250L tank

• 3-4 bedrooms: 30 tubes with 315L tank

• 4-5+ bedrooms: 44 tubes with 400L tank

Tanks

Tank options:

• 250L - Glass lined or stainless steel

• 315L - Most popular size

• 400L - Large families

Tank Brands: Apricus partners with various tank manufacturers including Everlast (marine-grade stainless steel), Thermann (glass lined), and others.

Key Components

Circulation pumps:

• Grundfos 15-20 CIL (most common)

• Wilo Yonos PICO-Z (newer systems)

• Lifespan: 5-8 years typically

• Cost: $600-$800 installed

Controllers:

• Resol DeltaSol BS/4 (4 sensor inputs)

• Resol DeltaSol BS/2 (2 sensor inputs)

• Resol ALE HE (newer models)

• German-made, highly configurable

Boosters

Boost options:

• Electric (bottom, mid, or top element)

• Gas continuous flow booster

• LPG options available

Evacuated Tubes Lost Vacuum

How it works:

Most unique Apricus problem! Copper heat pipes inside each glass tube transfer heat to the manifold. When they fail, performance drops dramatically even though tubes look fine.

How to check if vacuum is lost:

Barium getter test: Look at base of tube - SILVER = good vacuum, WHITE/MILKY = vacuum lost

Tube feels warmer to touch than others

Visible condensation inside the vacuum space

Tube was cracked and "repaired" (can't repair vacuum!)

Random tubes performing poorly

Common causes: Impact damage (hail, branches, birds), manufacturing defect in glass seal, age (15-20 years), thermal stress cracks from extreme temperature changes

Performance impact: On 30-tube system, losing 3 tubes = 10% performance loss. Losing 6-8 tubes = noticeable hot water shortage. System compensates until too many tubes fail.

Heat Pipe Failures Inside Evacuated Tubes

Panel condensation problems:

Most unique Apricus problem! Copper heat pipes inside each glass tube transfer heat to the manifold. When they fail, performance drops dramatically even though tubes look fine.

Heat pipe failure symptoms:

Collector only reaching 45-50°C on hot sunny days

Tank barely warming despite full sun

Need to {location.name}}run booster constantly

System worked great for 5-8 years, now lukewarm

Multiple tubes feel equally hot (no heat transfer)

What causes heat pipe failures:

Loss of vacuum inside heat pipe, copper compound degradation, too much/too little liquid inside pipe, freezing damage in cold climates, manufacturing defects from certain batches

Good news:

Apricus offers 15-year warranty on heat pipes! Many customers get free replacements at 5-7 years. Heat pipes can be replaced without replacing entire glass tube.

Manifold Temperature Sensor Failure

Sensor reading 25-27°C in full summer sun! This is THE most reported Apricus issue on forums. Manifold is scorching hot but sensor says it's cool, so pump never activates.

Manifold Sensor Problems:

Valves opening at 10-14°C (way above freezing)

Sensor reading only 25-30°C during peak sun

Pump not activating despite hot collector

Sensor loose in manifold socket (not glued in)

No heat sink grease for thermal contact

Sensor wiring corroded from weather

Water ingress in sensor porthole (design flaw)

Sensor reads correctly up to 55°C then random numbers

Critical fix:

Sensor MUST be snug in manifold slot with PLENTY of heat sink grease for thermal contact. Many installers skip this! Sensor just touching metal isn't enough.

Porthole design issue:

Apricus manifold sensor porthole allows water ingress which accelerates sensor failure. This is a known design weakness affecting many systems.

Manifold Cracking/Splitting (Freeze Damage)

Catastrophic failure! Manifold splits open from freezing water inside. System dead until manifold replaced. Expensive repair that's often warranty-denied.

How manifolds crack:

Blistering hot water from taps after dark

Temperature sensor failed to detect freezing conditions

Pump didn't circulate water for freeze protection

Power outage during cold night (pump can't run)

Isolation valves closed trapping water in manifold

Insufficient insulation on manifold

Apricus freeze protection: Controller circulates water once temp falls below 4°C. System rated to -15°C. BUT if sensor fails, pump fails, or power is out, freeze protection doesn't work!

Warranty battle:

Customer reports Apricus agreed to replace manifold for free BUT required customer to replace ALL components (pump, controller, sensors) at customer's cost "otherwise warranty void". Cost would be $2,000+ making repair uneconomical.

GRUNDFOS CIRCULATION PUMP FAILURE

Pumps last 5-8 years typically. Apricus uses quality Grundfos pumps but they still fail. Silent operation makes failure hard to detect - system just stops working!

Pump failure signs:

Pump completely silent (should hum quietly)

No vibration when touching pump body

Manifold getting dangerously hot

Tank not warming despite sunny weather

Controller shows high collector temp but no pumping

Pump failed within 2 years (warranty issue!)

Common issue:

First pump failed within 2 year warranty. Plumber didn't inform Apricus = warranty voided! Customer paid $600+ for replacement. Now on 3rd pump. Replacement pumps cost $700+ before installation!

Why pumps fail:

Bearing wear, impeller damage from debris, electrical failure, overheating, hard water scale buildup, cycling wear from frequent starts/stops.

Resol DeltaSol Controller Failures

Controller failed at 13 months - just out of warranty! Common complaint. Resol DeltaSol BS/4 and BS/2 controllers are German-made quality but failures still occur.

Controller problems:

Error code 888.8 displayed •

Incorrect temperature readings •

Pump running continuously at night (cooling water!) •

Pump not activating despite temperature differential •

Display blank/no power •

Faulty resistor in circuit (common at 13 months) •

New controller didn't fix problem (was sensors!)

Diagnostic trap:

Customer replaced controller for $$$. Problem persisted. Real issue was failed heat pipes! Always test sensors and heat pipes before replacing controller.

Positive note: Resol controllers have excellent diagnostics and adjustable settings for different climates. Brisbane vs Victoria systems need different parameter tuning.

Heat Pipe Migration/Disengagement

Heat pipes sliding down inside tubes! Bulbs at top of heat pipe disconnect from manifold sockets. System looks fine but produces no heat. Apricus redesigned with spring plates to fix this.

Migration symptoms:

Sudden dramatic performance drop

Tubes look normal, vacuum intact, but no heat

Bulbs visibly lower in manifold sockets

Affects multiple tubes gradually over time

Happened around 2-3 years after installation

The Problem: Original Apricus design had heat pipes held by friction alone. Thermal expansion/contraction caused pipes to slowly migrate downward. Bulb loses contact with manifold = no heat transfer.

The Fix: Apricus introduced spring plate assemblies to lock heat pipes in position. Existing systems need retrofit with spring plates when this happens. Apricus "reluctantly" supplied parts under warranty after fighting.

Tank Anode Depletion & Warranty Denials

Tank leaked at 6 years - warranty DENIED! Apricus/Thermann have 10-year tank warranty BUT strictly enforce anode replacement requirements. Many claims denied.

The warranty trap:

10-year tank warranty sounds great

Tank must be "regularly serviced"

Anode must be replaced "within recommended periods"

No specific interval stated clearly

Tank leaks at 5-6 years from anode depletion

Warranty claim: "anode degraded and not replaced" = DENIED

Customer complaints: "Apricus/Thermann do NOT honour warranty!" Multiple reports of 5-6 year tank failures denied due to lack of anode replacement proof, even with regular servicing.

Reality check: Almost NO homeowners replace anodes on schedule. Most don't even know they exist. Strict enforcement appears designed to avoid warranty claims.

System Running at Night (Pump Won't Stop)

Pump circulating after dark - cooling your water! System should shut off when collector cools down. If pump runs all night, it's actually COOLING your tank water.

Why pumps run at night:

Controller S MX (max temp) setting too high

Temperature differential settings wrong

Collector sensor failed reading incorrect temp

Controller stuck in manual ON mode

Freeze protection activating unnecessarily

Controller adjustment:

Resol controllers are very configurable but need proper setup for your climate. Brisbane systems vs Victoria systems need different settings. Apricus support can walk you through parameter adjustments over phone.

Freeze protection confusion:

System SHOULD run at night if temp drops below 4°C for freeze protection. This is normal in cold climates. But in Brisbane? Pump running at night = problem!

Tube End Seal Maintenance Required

Often neglected maintenance! Apricus systems require tube end sealing maintenance every 2-3 years. Most owners never do this, leading to gradual performance decline.

What needs maintenance:

Rubber seals at base of each tube

Seal between tube and manifold

O-rings and gaskets aging from UV/weather

Clips holding tubes in frame

Why this matters:

Degraded seals allow air infiltration into vacuum spaces (destroys insulation), moisture entry causing corrosion, tube movement in high winds, heat loss at manifold connection points.

Cost reality:

Customer complaint: "Not included is the tube end sealing maintenance on the roof that needs to be done every 2 to 3 years" in addition to pump replacements every few years. Hidden ongoing costs add up!

Air Locks in System

Pump running but no water flow! Air trapped in system prevents proper circulation. Common after installation, repairs, or when system runs dry.

Air lock symptoms:

Pump operating but no flow felt

Gurgling noises in pipes

System performance suddenly dropped

Happened after repairs/maintenance

Manifold overheating despite pump running

Proper purging:

System must be properly commissioned with careful air bleeding. Apricus installation manual has specific purging procedure. Rushed installations skip this!

Why Choose Todd's for Apricus Repairs?

Apricus evacuated tube systems are sophisticated technology requiring specialist knowledge. We have extensive experience with heat pipes, manifolds, and Resol controllers.

Local & family-owned – over 20 years working with solar, electric, gas and heat-pump systems on the Gold Coast

Bosch specialists – familiar all roof-mount and split systems

Fast, same-day hot water service – we prioritise no-hot-water jobs

Up-front quotes and clear explanations – no surprises

Repair or replace advice – we’ll always tell you honestly when a repair is worthwhile and when replacement will save you money and headaches long-term

Service Areas

We repair Apricus solar hot water systems across the Gold Coast, including:

Southport • Labrador • Arundel • Helensvale • Coomera • Upper Coomera • Runaway Bay • Hope Island • Robina • Varsity Lakes • Burleigh Heads • Burleigh Waters • Nerang • Pacific Pines • Molendinar • Paradise Point and surrounding suburbs.

Why Choose Todd’s Plumbing & Electrical

Family-owned Gold Coast business

20+ years specialising in solar hot water repairs

Licensed plumbers & electricians (no subcontractors)

Fast same-day service available

5-star local reviews & long-term customer relationships

Experts in Apricus system diagnostics

When you call us, you speak directly with a local team—not an offshore call centre.

Call the Bosch Solar Hot Water Expert

If your Aprcus solar hot water system isn’t performing, don’t wait for a total failure.

📞 Call Todd’s Plumbing & Electrical on 0482 080 423

We provide prompt, professional Apricus solar hot water repairs and honest advice across the Gold Coast and Brisbane.

Common questions about Apricus evacuated tube solar repairs in Brisbane

What are copper heat pipes and why do they fail in Apricus systems?

Heat pipes are the core technology in Apricus evacuated tubes. Each tube contains a copper pipe that's evacuated (vacuum inside) with a small amount of purified water mixed with copper compound.

How heat pipes work: When sun heats the tube, liquid inside heat pipe boils at very low temperature (~30°C due to vacuum). Vapor rises to bulb at top which plugs into manifold. Heat transfers to water flowing through manifold. Vapor condenses back to liquid and falls to bottom of heat pipe. Process repeats continuously.

Why heat pipes fail:

• Vacuum loss: If heat pipe loses vacuum, liquid won't boil properly = no heat transfer

• Wrong liquid amount: Too much water causes pressure buildup and burst pipes. Too little water = insufficient heat transfer

• Copper compound degradation: Apricus mixes copper compound with water to handle expansion during freezing. If ratio wrong or degraded, pipes burst in cold weather

• Manufacturing defects: Certain batches had quality issues with heat pipe production

• Freezing damage: Despite freeze resistance design, extreme cold without proper circulation can damage pipes

The good news: Apricus offers 15-year warranty on heat pipes! Many customers at 5-10 years get entire set replaced free under warranty. Heat pipes can be replaced without replacing glass tubes - just slide out old pipe, insert new one.

Typical symptoms: System worked perfectly for 5-8 years, then gradually performance dropped. Tank only reaching 40-50°C on sunny days instead of 70-80°C. Need to run booster constantly. All tubes look normal with silver barium getter (vacuum intact) but some tubes not transferring heat.

How do I know if my Apricus evacuated tubes have lost their vacuum?

The vacuum between the inner and outer glass tube is what makes evacuated tubes so efficient. When vacuum is lost, tube becomes an insulator instead of a collector!

The Barium Getter Test (easiest method):

• Look at the base/bottom of each evacuated tube

• SILVER COLOR = vacuum is intact (tube is good)

• WHITE or MILKY COLOR = vacuum is lost (tube needs replacement)

The barium getter is a metal coating deposited during manufacturing that turns white when exposed to air/oxygen. It's a visual indicator of vacuum integrity!

The Infrared Thermometer Test (more accurate):

• Use IR thermometer on outside of glass tube at bottom

• Test while pump is running in full sun

• Check every tube and compare readings

• Tubes with lost vacuum read 3-4°C HOTTER than good tubes

• Why? Failed tube not extracting heat to manifold, so glass stays hotter

Other signs of vacuum loss:

• Visible condensation between glass layers

• Tube feels warmer to touch than others

• Tube had visible crack (can't repair vacuum!)

• Random tubes performing poorly

• System performance dropped but heat pipes test OK

How many failed tubes matter? On 30-tube system, 1-2 failed tubes = barely noticeable. 3-5 failed tubes = 10-15% performance loss. 6-10 failed tubes = significant hot water shortage. System gradually compensates until too many tubes fail.

Common causes: Impact damage (hail, branches falling), manufacturing defects in glass seal, age (15-20+ years), thermal stress from rapid temperature changes, improper handling during installation

Why is my Apricus roof sensor reading only 25-27°C in full sun?

This is THE most commonly reported Apricus problem on forums! Manifold is scorching hot (70-90°C) but sensor reads cool (25-30°C), so controller thinks no heat available and doesn't activate pump.

Most common cause: Sensor not making thermal contact

• Sensor probe is loose in manifold socket

• No heat sink grease/thermal paste applied

• Sensor just touching metal isn't enough!

• Sensor needs to be SNUG in slot with PLENTY of thermal compound

• Many installers skip the thermal paste!

Water ingress issue (design flaw): Apricus manifold sensor porthole design allows water to get in, which corrodes sensor and connections. Multiple users report this as a known weakness. Water ingress accelerates sensor failure dramatically.

Sensor failure patterns:

• Reads correctly up to 55°C then gives random numbers above that

• Stuck at fixed temperature (25°C, 30°C, etc) regardless of actual heat

• Intermittent readings - works some days, fails other days

• Reading drops when cable is jiggled (wiring issue)

Other causes: Corroded wiring from weather exposure, bird/rodent damage to cables, sensor itself failed internally (less common), wrong sensor type installed, poor crimped connections

The fix: Replace sensor ($180-$350). CRITICAL: New sensor MUST be installed with heat sink grease and pressed firmly into manifold socket. Consider sealing porthole better to prevent future water ingress. Test sensor resistance with multimeter to confirm it's working before assuming it's installed correctly.

Don't assume it's the controller! One customer replaced expensive Resol controller thinking it was faulty. Problem persisted. Real issue was manifold sensor not making proper contact. Always test sensors first before replacing controller!

How does Apricus's 15-year heat pipe warranty work?

Apricus offers excellent 15-year warranty on heat pipes and evacuated tubes! This is one of their best features. Many customers report successful warranty claims at 5-10 years.

What's covered under warranty:

• Heat pipes: 15 years (including copper compound degradation)

• Evacuated tubes: 15 years (glass and vacuum)

• Copper manifold/header: 15 years

• Aluminum frame: 15 years

• Tank: 10 years parts only (strict conditions!)

• Pump: 2 years typically

• Controller: 2-3 years typically

How to make a claim:

• Contact Apricus: 1300 277 428 or [email protected]

• Provide system details (serial number from tank label)

• Describe problem and symptoms

• They'll guide you through diagnostic tests

• May need photos or installer inspection

• If approved, parts shipped free

Positive warranty experiences: Multiple customers report "Ros was very helpful with warranty claim. My system is 5 years, all heat tubes were replaced after speaking with Ros and a couple of emails. Great service." Another: "After 15 years of service needed new pump. Ros found replacement quickly, arrived next day."

Common approved claims: Heat pipe degradation after 5-10 years, evacuated tubes from faulty batch, manifold issues, collector frame corrosion

Warranty EXCLUSIONS (read carefully!):

• Damage from incorrect installation

• Lack of maintenance (tank anode not replaced!)

• Damage from freezing below -15°C

• Bird/animal/storm/vandalism damage

• Lightning strikes, power surges

• Collector left dry (no circulation) in full sun

• Labour costs (parts free, you pay installer)

Tank warranty TRAP: 10-year tank warranty sounds great BUT strictly requires "regular maintenance" and anode replacement "within recommended periods." Many claims denied at 5-6 years: "Failure due to tank corrosion where magnesium anode degraded and not replaced." Customer must prove anode maintenance! Other solar brands don't enforce this as strictly.

Why does Apricus require more maintenance than other solar systems?

Apricus evacuated tube systems are sophisticated technology that delivers excellent performance but requires more attention than simple flat plate systems.

Required maintenance schedule:

• Every 2-3 years: Tube end seal maintenance ($300-$500)

• Every 3-5 years: Tank anode inspection/replacement ($280-$450)

• Every 5-8 years: Circulation pump replacement ($600-$800)

• As needed: Clean tubes if in dusty area, check sensor connections, verify controller settings

Why more maintenance?

• Multiple O-rings and seals: Each tube has seals that age from UV/weather

• Complex components: Heat pipes, sensors, controllers have more failure points than simple systems

• Exposed roof installation: Wiring, sensors, collectors all exposed to weather and wildlife

• Active system: Pump and controller add moving parts and electronics that fail

• Strict warranty enforcement: Apricus actually enforces maintenance requirements for warranty (other brands don't)

Hidden ongoing costs: Customer complaint: "Because tank is at ground level, collectors at roof level require water constantly pumped... This is great until recirculating pump fails. Original pump failed in less than 2 warranty years, had to replace at $600+ because plumber didn't inform Apricus (voided warranty). My 3rd pump now showing signs of wear, replacement $700+ BEFORE installation. Current pumps only 2-year warranty, making this quite expensive long term. Not included is tube end sealing maintenance every 2-3 years."

Reality check: Total ownership cost over 15 years can include: 2-3 pump replacements ($1,200-$2,400), 1 controller replacement ($450-$750), 5-7 seal maintenance services ($1,500-$3,500), 3-5 anode replacements ($840-$2,250), possible heat pipe replacements (often warranty covered). Total = $4,000-$9,000 in maintenance beyond initial purchase.

Compare to flat plate systems: Simple flat plate collectors have fewer components, no O-rings on every tube, fewer electronics, generally need pump replacement and occasional valve work but that's about it.

Is it worth it? Apricus systems DO provide excellent performance - often 80-90% solar contribution in Brisbane. They work better in shade/clouds than flat plates. They're freeze-proof to -15°C. If you're willing to invest in proper maintenance, they're great systems. If you want "set and forget", consider simpler technology.

Is my Apricus worth repairing or should I replace it?

This depends on system age, what's failed, and total repair costs. We give honest advice based on your specific situation.

REPAIR usually makes sense when:

• System under 10 years old with single component failure

• Heat pipes failed: Often covered by 15-year warranty (free parts!)

• Sensor or pump failure: $180-$800 repair extends system life years

• Few evacuated tubes failed: Easy to replace individual tubes

• Tank is good condition: No leaks, anode has life left

• Total repairs under $1,500 and system could last 5+ more years

REPLACEMENT makes more sense when:

• Tank leaking: Especially if anode-related = warranty denied. Tank replacement $2,500-$4,000 alone!

• System 12-15+ years old with multiple failing components

• Manifold cracked: $800-$1,500 repair + other issues adding up

• Multiple heat pipes AND evacuated tubes failed: Even with warranty, labour costs high

• This is 3rd or 4th repair: Throwing good money after bad

• Total repair costs $2,000+ on system over 10 years old

Real customer scenarios:

Scenario 1: 7-year-old system, heat pipes failing, lukewarm water.

Verdict: REPAIR. Heat pipes covered by 15-year warranty! Free parts, just pay labour ($300-$500). System should run another 8+ years.

Scenario 2: 14-year-old system, tank leaking, pump failed, several tubes lost vacuum.

Verdict: REPLACE. Tank alone $3,000+, pump $700, tubes $500+. Total $4,200+ on system near end of life. New system $4,500-$6,000 with full warranties.

Scenario 3: 6-year-old system, sensor failed, pump making noise.

Verdict: REPAIR. Sensor $300, pump $700 = $1,000 total. System mid-life, worth keeping.

Modern alternatives: Today's solar systems (Apricus still makes them! Plus Solahart, Rheem, Edwards) have improved reliability. New Apricus system 315L with 30 tubes costs $4,500-$6,500 installed with full warranties. Heat pumps ($3,500-$5,000) are also excellent alternative - no roof collector, simpler technology, very efficient.

Our assessment process: We inspect entire system - not just immediate problem. We check: tube condition (vacuum test), heat pipe performance (IR thermometer), pump operation, controller function, sensor accuracy, tank condition, anode status, manifold integrity. We then give you: (1) Cost to repair with realistic expected life, (2) Cost to replace with new system performance comparison, (3) Which option makes better financial sense, (4) What we'd do if it was our house.

How much does it cost to repair an Apricus solar system?

Typical Brisbane pricing for common Apricus repairs:

Evacuated Tube & Heat Pipe Repairs:

• Heat pipe replacement: $50-$80 per tube (just the copper pipe inside)

• Evacuated tube replacement: $80-$120 per tube (entire glass tube)

• Complete tube + heat pipe: $120-$180 per tube

• Labour for tube work: $150-$300 depending on number of tubes

• Full system tube refresh (all 30): Often warranty covered (just pay labour $300-$500)

Sensor & Controller Repairs:

• Manifold/collector sensor: $180-$350 (includes heat sink grease, proper installation)

• Tank sensor: $150-$300

• Sensor cable replacement: $200-$400 (bird damage, corrosion)

• Resol controller replacement: $450-$750

• Controller settings adjustment: $150-$300

Pump & Circulation:

• Grundfos pump replacement: $600-$800 installed

• Wilo pump replacement: $550-$750 installed

• System purging/air lock removal: $180-$350

• Check valve replacement: $150-$280

Manifold & Collector Repairs:

• Manifold seal replacement: $250-$450

• Tube end seal maintenance: $300-$500 (all tubes)

• Manifold replacement: $800-$1,500 (major repair)

• Spring plate retrofit: $400-$700 (heat pipe migration fix)

Tank & Plumbing:

• Sacrificial anode replacement: $280-$450

• Pressure relief valve: $180-$320

• Tempering valve: $200-$380

• Tank replacement (if leaking): $2,500-$4,000

• Electric element: $300-$500

Diagnostic & Assessment:

• Full system assessment: $150-$300 (vacuum testing, heat pipe testing, sensor checks)

• IR thermometer testing (all tubes): Included in assessment

• Performance monitoring: $100-$200

Our pricing is transparent: We quote before starting work. Price includes quality parts, labour, testing, and warranty on our work. If additional problems found, we contact you before proceeding.

Warranty repairs: If heat pipes or tubes are under 15-year warranty, parts are FREE from Apricus. You only pay our labour ($300-$500 typically). We help you with warranty claim process and documentation.

Cost comparison: Most Apricus repairs are $300-$800 for single component failures. New system costs $4,500-$6,500. If system under 10 years old, repair almost always makes sense. If system 12-15+ years with multiple issues, replacement may be better value.

How long should I expect my Apricus system to last?

Realistic lifespan expectations for Apricus evacuated tube systems with proper maintenance:

Overall system lifespan: 15-20 years with regular maintenance and component replacements as needed.

Component lifespans:

• Evacuated tubes: 15-25 years (vacuum loss is gradual, not sudden)

• Heat pipes: 10-15 years (often fail around 7-10 years, warranty covers 15 years)

• Storage tank: 10-15 years IF anode maintained every 3-5 years. Without anode maintenance, tanks fail at 5-8 years

• Circulation pump: 5-8 years (Grundfos quality but gets heavy use)

• Controller: 10-15 years (electronics last well, power surges/lightning main killers)

• Temperature sensors: 8-12 years (weather exposure, water ingress causes failures)

• Manifold: 15-20+ years (unless freeze damage)

• Tube seals/O-rings: 2-3 years (require regular maintenance)

• Aluminum frame: 20+ years (corrosion-resistant, very durable)

Real-world examples:

• "I have had my Apricus system for more than 15 years. For majority of this time, unit performed extremely well." - After 15 years needed heat pipe replacement (warranty covered) and pump replacement

• "30 tube system, about 9 years old" - Heat output declining, needed diagnostics

• "System worked brilliantly for two years and recently stopped working" - Turned out to be faulty tube batch

• "After 15 years needed new pump" - Everything else still working fine

Maintenance impact on lifespan:

• With proper maintenance: 18-20+ years achievable. Customer reports: "That's past 15 years of reliable hot water service which has paid for itself over and over in cheaper electricity bills."

• With neglected maintenance: 8-12 years typical. Tank fails early from anode depletion, seals deteriorate causing vacuum loss, pump burns out from debris

Expected replacement schedule:

• Years 0-5: Usually trouble-free, maybe sensor issue

• Years 5-8: First pump replacement likely, possible heat pipe degradation (warranty claim), tube seal maintenance

• Years 8-12: Second pump replacement, more heat pipes may need replacement, possible controller issues, tank anode definitely needs replacement

• Years 12-15: Major service decision point - is system worth keeping? May need tank replacement, third pump, multiple tubes

• Years 15-20: If you've maintained well and replaced components, system can keep going. Many tubes likely need replacement, frame/manifold usually still good

When to replace vs repair: After 12-15 years, if facing major repairs ($2,000+), replacement with modern system often makes more sense. New Apricus systems have improved designs addressing many early issues. Alternative technologies (heat pumps, improved flat plates) may also be worth considering.

Bottom line: With diligent maintenance, Apricus systems deliver excellent 15-20 year service life. Without maintenance, expect 8-12 years with warranty hassles. Budget $400-$800 every few years for maintenance and component replacements throughout system life.

If it can't be fixed we can supply a new system from as little as $24 a week

Over 22 Years of 5-star Rated Service

Solar Hot Water Brands We Service & Repair

Aquamax

Apricus

Beasley

Bosch

Chromagen

Conergy

Dux

Ecosmart

Envirosun

Edwards

Everhot

Hills

Leda

Quantum

Midea

Neopower

Reece

Rheem

Rinnai

Sanden

Saxon

Stiebel Electron

Solahart

Solargain

Solar Oz Solar

Power Sun Ray

Sun Solar

Thermasun

Vulcan

Finance Available

Solar Hot Water Repairs Across The Gold Coast & up to Brisbane

Hot Water System Repairs & Replacement Experts

Electric Hot Water

Heat Pumps

Gast Hot Water

Roof Mounted

Solar Hot Water

Split System

Solar Hot Water

Solar Power

Systems

Get A Free Quote

Submit your details or call 0482 080 423

Head Office

1/28 central Park Avenue, Ashmore, Qld, 4214

0482 080 423

1300 609 606

QBCC: 1126780

Electrical License Number: 71053

We accept cash, direct deposits, and all major CC's